-40%

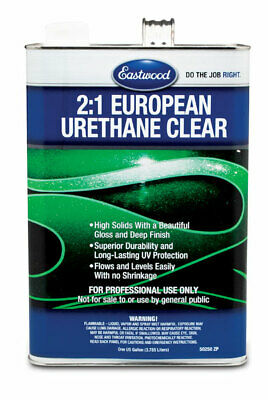

Eastwood 2:1 Urethane Super Durability Clear Coat Activator System UV protection

$ 57.54

- Description

- Size Guide

Description

*** THIS PAINT REQUIRES AN ACTIVATOR TO CURE PROPERLY THAT IS NOT INCLUDED ****** Mixes 2:1 With 50252ZP Eastwood Urethane Clear 2:1 Activator ***

Click Here For Activator

Premium European resins in this Urethane Clearcoat produce excellent durability and UV resistance.

Mixes 2:1 With Activator

(Not Included)

Easy to spray flat, and even easier to polish

Long-lasting protection from UV, chemicals and weathering

High-solids content to build quickly and avoid shrink-back as it cures

Approximate Coverage Per Gallon: 150 SQ FT

Maximum operating temperature: 150 Fahrenheit

Eastwood Euro Urethane Clear is a premium 2:1, high-solids clearcoat made from superior European resins. It dries fast, with a beautiful gloss and excellent DOI. Flows and levels easily with no shrinkage or dieback. Features excellent durability and long-lasting UV protection, weathering and everyday wear. Mixes 2:1, 2 parts clear (1 Gallon), 1 part activator (2 Quarts).

MIXING RATIO

Thoroughly mix two parts 50250ZP HS Clear in gallons or 50251ZP HS Clear in quarts, with one part 50252ZP HS Clear Activator. For even better spray-ability, 2:1 mix may be reduced with a urethane-grade reducer or other appropriate solvent product. Doing this will improve the flow and leveling. Eastwood suggests using a Zero-VOC reducer to avoid potential compliance issues.

Use caution in mixing materials as HS Clear may begin to gel after approximately two hours (at 70 °F).

SPRAY GUN SETUP

HVLP Gun: Fluid Tip 1.3-1.5 mm Inlet Spray Pressure 25-30 psi

Conventional Gravity: Fluid Tip 1.3-1.6 mm Inlet Spray Pressure 45-50 psi

Conventional Siphon: Fluid Tip: 1.4-1.8 mm Inlet Spray Pressure 45-50 psi

APPLICATION INSTRUCTIONS

Apply Eastwood HS Clear in two medium wet coats, with a 10-minute flash period be- tween each. Clear should be dry to the touch within 10 minutes, and will be tack-free within three hours (at 70 °F). Do not recoat between one and eight hours after previous coat. Additional coats may be applied after eight, but before 18 hours (at 70 °F) have passed from completion of previous coat. Ideal application temperature is between 70°F and 90°F.

For increased depth and gloss, well cured clear may be wet sanded and recoated with one to two additional wet coats.