-40%

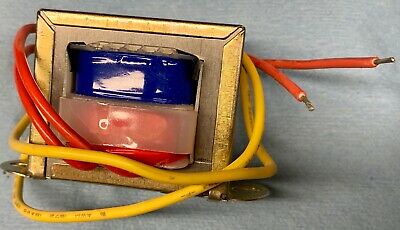

800VA 70V TOROIDAL TRANSFORMER for CLOSED LOOP STEPPER HYBRID SERVO MOTOR CNC

$ 49.1

- Description

- Size Guide

Description

If you’re sourcing a transformer for your closed loop stepper system based on the popular 24-80VAC drives, this is the right one:•

OPTIMIZED VOLTAGE.

Voltage is the pressure that forces current into the stepper’s coils.

The faster the rotor turns, the less time for the coils to saturate, hence

torque falls as speed increases. Few toroids being offered for stepper

motor application put out more than 60V. That’s not bad, but the

sweet spot for motor performance is 70V. This leaves a 10V margin

to ensure long life for the drive.

•

MOST EFFICIENT DESIGN.

Toroidal transformers are well-suited for noise sensitive

environments such as CNC control cabinets and powering stepper

and servo drives. Voltage drop under high current draw is very low,

which is important when your depending on relies on relays,

solenoids, etc to operate reliably.

•

FIRST RATE MATERIALS & BUILD QUALITY.

Construction materials meet all major industry standards including

100% copper wire, Nippon Steel Co. core material, ROHS compliant,

UL standards and CE certifications. Check the jpeg attachments for

the bill of materials quality standards.

SPECIFICATIONS

Rated Power: 800VA

Input: 110-120VAC -- RED-RED, 50-60Hz

Output: 70VAC -- BLU-BLU

Output Current: 11.43A

Outer Dia: 6.5”

Height: 3.15”

Weight: 16.3 lbs.

NOTE: Toroidal transformers are typically sized overkill due to overlooked information. You may not need 800VA for your control system. Bear in mind the following factors:

SIZING TRANSFORMERS FOR CLOSED LOOP STEPPER SYSTEMS

The conventional wisdom propagated on the internet is that the transformer VA rating should be 2/3 of the combined current of the motors at their operating voltage.

For example: Three 6A steppers operating at 70VDC would require a 840VA transformer. The problem with this formula is that it ignores four important factors:

1) Steppers recirculate current within the motor windings and dump back into the power supply as opposed to constantly drawing current. This happens because of the following fact . . . .

2) A stepper motor can only absorb its rated current when the rotor is stationary or nearly so. The faster the rotor turns, the less time there is to saturate the coils, so the coils seldom saturate more than a fraction of the rated current. The evidence of this is seen in the torque fall off as rotor speed increases.

3) It is often overlooked that transformers, being electromagnetic devices, are rated at continuous output. Peak current output is 3X the rated output. You read that right. A transformer can far exceed its rated output at limited intervals to meet high moment loads

. The actual limiting factor is the excess heat generated by the overload which can shorten the life or damage other components in the controller box in extreme cases.

4) Two, three or even four steppers—believe it or not—typically don't draw much more current than one. This is because the load of a work piece moving against a cutting tool is approximately the same whether one or three axes drive the workpiece into the cutter.

TRANSFORMER SIZING FORMULA

STEP ONE

Determine base volt/amp value by averaging the total number of motors’ rated current and multiplying it by the desired operating voltage.

Take for example a 3 Axis system. If the X and Y axes are driven by 6A motors and the Z axis is driven by a 5A motor, the average current will be 5.7A. If the desired voltage is 70VAC, the equation will be:

70V X 5.7A = 400VA (rounded)

STEP TWO

The base value of 400VA represents one averaged axis. Now we need to add the other two axes power requirements.

With 400VA as the base value, add 1/3 of that same value for each additional motor. Again, this is based on the averaged current. So with 400VA divided into three we get 133VA that we need to add for each of the other two motors. This gives us an averaged total power requirement of 660VA for all three motors. So a 650VA transformer would be more than up to the job in our example.

THE CLOSED LOOP FACTOR

In the case of steppers driven in closed loop there is an additional factor worth taking into consideration. Current delivery to the motor is variable based on the load requirement at any given point. This goes both ways. An axis with a consistently high torque requirement will trigger the drive to respond by forcing more current into the motor’s coils often. Conversely, an axis with less load requirement will draw less than the formula's average. On such axes, the values of the formula should be modified to account for the increase or decrease in power requirement.

Bear in mind

that both oversizing and undersized the transformer can create excessive heat in the control box shortening the life of the components.

Ships from Palmdale, CA to the lower 48 states only.